Die Casting Tool Design Pdf

Design For Die Casting (Spanner).

The Dies are usually made of alloy or tool steel and are quite expensive to make. Some have one or two identical mould cavities for larger parts, and others may have several different cavities. Some dies are more complicated and have sections that move in several directions. Grooves or overflows around the cavity on the parting face permit gases to escape. [2]The overflows of excess metal must be trims off by a secondary operation after the casting is removed from the mould. This trimming is done with trimming dies that also removes the sprues and runners. The mould must also have provisions for water cooling so that a constant operating temperature can be maintained. Knock-out pins provides for injection the parts when the die is opened. When cores are used they are made of metal and are usually drawn out before the die is opened. Cores are retracted either in a straight line or in circular motion.

Baca lebih lanjut

24 Baca lebih lajut

1f handbook die casting proceses edwadrd j virnacik 2003

Stereo prototyping methods are also being developed for direct production of die cavity tooling. Instead of using liquid resin, laser sintering with metal powder has been used in the development of this technology. Experimentation is underway utilizing several dif- ferent nontraditional metal powders, including polymer-coated zir- conium diboride, bronze–nickel mixtures, and 316 stainless steel. Casting cavity inserts are also being produced using an indirect form of rapid prototyping. Wax patterns of a casting cavity can be produced using polymer stereo lithography technology. These patterns can then be investment cast, producing die cast tooling inserts in H13 tool steel. However, the investment casting method has several problems. Large metal masses such as a casting cavity inserts are difficult to cast, resulting in porosity and distortion. To overcome these problems, experimentation is underway to test hollow casting cavity inserts investment cast with a uniform thick- ness.

Baca lebih lanjut

232 Baca lebih lajut

Design and Simulation on Investment Casting Mold for Metal Matrix Composite Material.

An automotive part, compressor impeller will be used as the product for the casting mold. Aluminum-based alloys are the common material for automotive part. Alloys with an aluminum base have a wide range of mechanical properties, mainly because of various hardening mechanisms and heat treatments that can be used with them. An increasing trend is their use in automobiles, for components such as engine blocks, cylinder heads, intake manifolds, transmission, cases, suspension components, wheel and brakes. A part made of aluminum-based and magnesium based alloy are known as light-metal casting.

Baca lebih lanjut

7 Baca lebih lajut

Design and optimization of runner and gating systems for permanent mould casting.

area was increased and the gating speed was slightly reduced [ 4 ]. Gating design was considered in designing of mould, for example as a method of 3D geometries construction [ 5 ], angles of the branches [ 6 ], and weighting method [ 7 ]. Most of the researchers have been applied the gating system for the die casting [ 4-7 ]. In December 2013, the authors determined the causes of failures and repairing alternatives in designing of mould and die [ 8 ].

7 Baca lebih lajut

Process optimization for DIE manufacturing: EDM die sinking.

Machining is a term that covers a large collection of manufacturing processes designed to remove unwanted material, usually in the form of chips, from a workpiece. Machining is used to convert castings, forgings, or preformed blocks of metal into desired shapes, with size and finish specified to fulfil design requirements. Almost every manufactured product has components that require machining, often to great precision. Therefore, this collection of processes is one of the most important of the basic manufacturing processes because of the value added to the final product. By the same token, machining processes are often the most expensive. The majority of industrial applications of machining are in metals. Although the metal cutting process has resisted theoretical analysis because of its complexity, the application of these processes in the industrial world is widespread. Machining processes are performed on a wide variety of machine tools (J. T. Black, 1990).

Baca lebih lanjut

24 Baca lebih lajut

Design Of Casting Mold For Natural Fiber – Metal Matrix Composite Material.

Problems that should highlight here is the metal matrix composite (MMC) melted up to 700 and then only will poured in sand casting and it is an open mould. A study on thermal flow should be conducted to get a laminar flow for molten MMC during filling the mold, so no defects occurred in it. This study will conduct by suggesting few designs to fill molten metal into the open mould sand casting. At this temperature also, natural fiber will vanish so there is challenges to get to know the suitable temperature for add the natural fiber into the solidifying molten metal.

Baca lebih lanjut

24 Baca lebih lajut

Design and simulation of investment casting mold for obsolete automotive part.

Most of the automotive parts for this motorcycle made from casting process. The making of automotive parts in huge and mass production for this motorcycle usually uses investment-casting method. Investment casting is an industrial method and was also known as lost-wax casting. Investment casting allocates the production of parts with better accuracy, repeatability, versatility and integrity in a variety of metals and high-performances alloys. Investment casting can manufacture complicated shapes

24 Baca lebih lajut

Design And Development Casting Mould Pattern (Keris).

No other weapon so characterizes the Malay world as the keris, an elongated dagger. Surrounded by a wealth of lore, it has always been an object of intense curiosity and interest to outsiders. The keris which has special significance has been used as weapons of self defence used by Malays for generations. In the last century, it evolved from a royal weapon of choice to a status symbol in Malay history. The degree of elaborate designs dictated the status in old Malay hierarchy. However, today the keris and other traditional weapons are more for ceremonial and decorative purposes and remain as a Malay Heritage.

Baca lebih lanjut

24 Baca lebih lajut

Kekuatan Tarik Dan Porositas Silinder Al-Mg-Si Hasil Die Casting Dengan Variasi Tekanan

Tensile strength and porosity of die-casted Aluminum Alloys Al-Mg-Si with various applied pressure were investigated. Al-Mg-Si was melt in the electric induction crucible with temperature of 850 degree Celsius. Melt aluminum was poured in the metallic mould that pre- heated in 150 degree Celsius. Melt aluminum was pressed by the plunger with pressure of 0.1, 10, 30, and 50 MPa and held for 5 minutes. After aluminum was solidified, specimens for tensile strength and porosity test were machined. Tensile strength, porosity test and microstructure observation were conducted. Results of tensile strength and porosity test show that the higher plunger pressure, porosity becomes lower and tensile strength of specimens to be higher. Maximum tensile strength occurs in the specimens that pressed in 50 MPa. It occurs due to minimum porosity and small grains of microstructure in the specimens.

Baca lebih lanjut

6 Baca lebih lajut

Design, Analysis And Simulation Of Casting Defect On Water Pump Housing Using Casting Simulation Software.

The first step is the preparation and clamping of the two halves of the die. Each die half is first cleaned from the previous injection and then lubricated to facilitate the ejection of the next part. The lubrication time increases with part size, as well as the number of cavities and side-cores. Also, lubrication may not be required after each cycle, but after 2 or 3 cycles, depending upon the material. After lubrication, the two die halves, which are attached inside the die casting machine, are closed and securely clamped together.

Baca lebih lanjut

24 Baca lebih lajut

Design And Model Making Of Bending Die.

Dear mummy and daddy at Ranau Sabah, thanks for your prayer, emotion, and financial support. Not to forget my long distance sister, Frances. Far away doesn' t means we are separate. Straight in our heart, we are always together. Thanks for strengthen me each time I'm feeling down. I would like to thanks all that supported me from everywhere. God richly bless you all.

24 Baca lebih lajut

Design And Analysis Of Step Clamp Using Sand Casting And Rapid Prototyping.

The title of this project is Design and Analysis of Step Clamp Using Sand Casting and Rapid Prototyping. The project was staretd by identified the problem statement, and the objective which is to investigate the design parameter of sand casting for step clamp, to design a casting mold base on the optimum parameter using CAD tools such as Solidwork and to analyzed the sand casting mold using CAD software such as ANSYS. The chosen manufacturing tool, Step Clamp was design by using Solidwork and converted into STL file to tranform the design into casting pattern by using Rapid-prototyping process. Then, nine design concept of the casting mold were designed and were analyzed by using ANSYS according to the analysis parameter set. Based on the analysis, the comparison had been made and the best design concept has been selected which is siutable to use in the sand casting process

Baca lebih lanjut

24 Baca lebih lajut

1g handbook die design 2nd edition

A partially bent-up part from Fig. 1-46 is quite another challenge yet. Here the high rec- tangular boss draws so much material from the strip that all three edges cave in, as shown in the areas marked A and B. Since a small bend was to be produced in the A section later on (see Fig. 1-47), the straight line of the cut was of essence. The die sequence already being in place (Fig. 1-48), there was no chance of switching the cutoff operation to the end. As the distortion of the part's sides (areas B) did not matter to the customer, the die designer concentrated on the area A only where a previously straight cut was replaced with a rounded arc (see Fig. 1-49). This way the extra material thus added to the part in flat could be used up for the formation of the rectangular boss, and the final product with its A flange straight, is shown in Fig. 1-50.

Baca lebih lanjut

714 Baca lebih lajut

Design And Development Casting Mould For Resin Based Medals.

Casting is a manufacturing process by which a molten material such as metal or plastic is introduced in a mold, allowed to solidify within the mold, and then ejected or broken out to make a fabricated part. Casting is used for making parts of complex shape that would be difficult or uneconomical to make by other methods, such as cutting from solid material [22].

24 Baca lebih lajut

Design Simulation of Filing Sequence and Solidification Time for Cast Metal Matrix Composite by Low Pressure Die Casting.

Abstract – Experimental and theoretical studies are realized in order to verify the Mini Heat Pipe (MHP) concept for cooling high power dissipation electronic components, and determine the potential advantages of constructing mini channels as an integrated part of a flat heat pipe. In the experimental part of this study, a Flat Mini Heat Pipe (FMHP) prototype including a capillary structure composed of parallel rectangular microchannels is manufactured and a filling apparatus is developed in order to charge such FMHPs. The heat transfer improvement obtained by comparing the heat pipe thermal resistance to the heat conduction thermal resistance of a copper plate having the same dimensions as the tested FMHP is demonstrated for different heat input flux rates, heat sink temperatures, and orientations. In the theoretical part of this work, a detailed mathematical model of a FMHP with axial microchannels is developed in which the fluid flow is considered along with the heat and mass transfer processes during evaporation and condensation. The model is based on the equations for the mass, momentum and energy conservation, which are written for the evaporator, adiabatic, and condenser zones. The model, which permits to simulate several shapes of microchannels, can predict the maximum heat transfer capacity of FMHP, the optimal fluid mass, and the flow parameters along the microchannel. The comparison between experimental and model results shows the good ability of the numerical model to predict the axial temperature distribution along the FMHP. Copyright © 2011 Praise Worthy Prize S.r.l. - All rights reserved.

Baca lebih lanjut

170 Baca lebih lajut

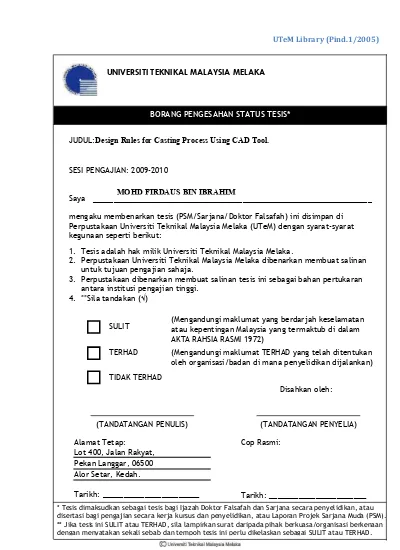

Design Rules For Casting Process Using CAD Tool.

Malaysia has grown up as of developing country in the world. Malaysia has made it clear as their Gross National Product (GDP) is 6% to 7% per year. As consequence, there are lot of Malaysian manufacturers have been setup in years. There are 2% of Malaysian manufacturers who are applying casting technology for their businesses out of over 2000 manufacturers registered at Federation of Malaysian Manufacturers. This shown that there is plenty company who make use of casting technology.

24 Baca lebih lajut

INTRODUCTION DESIGN OF VULCANIZER FOR SPIN CASTING TECHNOLOGY.

Universitas Atma Jaya Yogyakarta efforts to run souvenir production by applying the spin casting technology must be supported by presenting the vulcanizer to obtain vulcanized silicone rubber as the mold. Hence this thesis will present the design phase and construction of vulcanizer after finding appropriate type of silicone rubber, refer to the need of integrating the mold and the spin casting machine itself.

5 Baca lebih lajut

Die Casting Tool Design Pdf

Source: https://123dok.com/title/design-for-die-casting-spanner

Posted by: brownsown1945.blogspot.com

0 Response to "Die Casting Tool Design Pdf"

Post a Comment